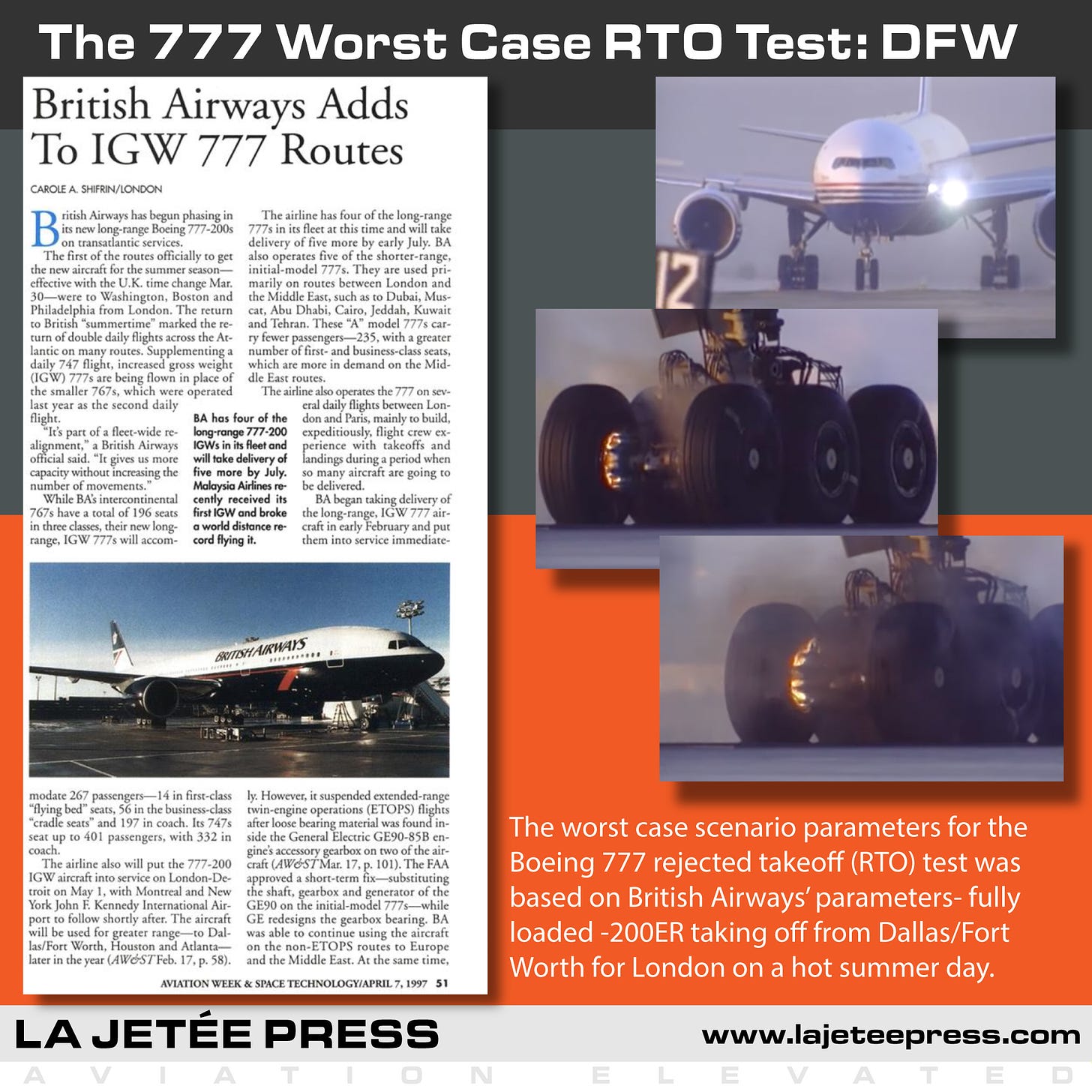

The Boeing 777 Worst Case Rejected Take-Off Test: Dallas/Fort Worth

The worst case scenario in a rejected take off scenario for the Boeing 777 belonged to British Airways- a hot day at DFW, fully loaded for London.

When the 777 was in flight testing, the Boeing and FAA engineers were preparing for the maximum weight rejected takeoff (RTO) test called "The Big One"- this was the worst case scenario- full payload, maximum brakes, and brakes purposely worn down to remove any additional safety margin.

As test preparations were under way, British Airways notified Boeing that they planned to use the 777-200ER on the London Gatwick-Dallas/Fort Worth route and this required an increase in the payload weight and takeoff speeds (thus maximum braking forces) than what Boeing was originally prepared to perform as "The Big One".

It was BA's worst case scenario- an aborted takeoff out of DFW on a hot summer day and it was worse than what the Boeing engineers had considered the worst case scenario.

After a lot of hand-wringing, they went ahead and conducted "The Big One" using BA's DFW parameters. The jet was loaded to a takeoff weight of 632,000 pounds, accelerated to 183 knots, then 100% braking applied as thrust went to idle. The 777 stopped in 4000 feet, the brake temperatures went off the scale past 3000 degrees Celsius, and as the 777 turned off the runway, smoke could be seen from the brakes as they glowed white hot.

With the fire trucks standing by for the required five minutes (to simulate time to reach the aircraft), the first tire blew (in a controlled manner using what's called a fuse plug in such emergencies- the plug melts and lets air out without a blowout) before the plane stopped. All 12 tires' fuse plugs blew and steam billowed out from the wheels as the fire trucks pumped water on the undercarriage.

The 777 passed "The Even Bigger One".